Manufacturing Facilities

Manufacturing Facilities

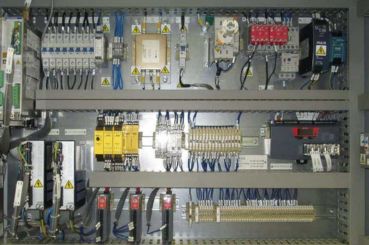

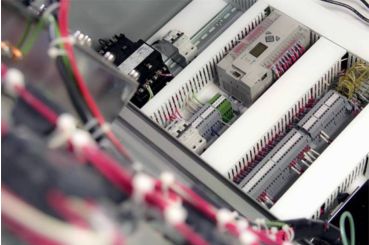

The organization boasts a cutting-edge manufacturing facility dedicated to electrical control panels, equipped with the latest machinery and technologies. Operated by a skilled team of experienced technicians, the facility ensures precision and efficiency in every stage of production. Comprising various units including fabrication, electrical wiring and assembly, and in-house testing and measuring facilities, our power control panels manufacturing unit is fully integrated to deliver high-quality products. With a commitment to innovation and excellence, we strive to meet the diverse needs of our clientele with reliability and expertise.

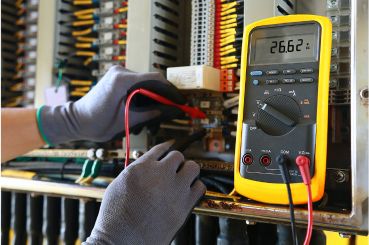

In-house Testing Facilities

- High Voltage Test

- Megger Test

- Conductivity Test

- Continuity Test

- Multi Meter Test

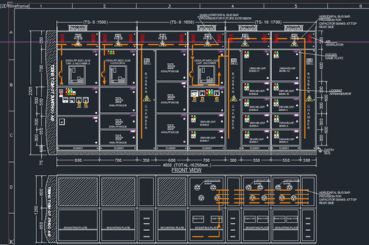

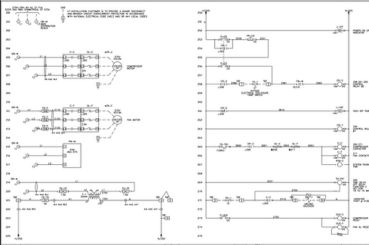

Designing & Engineering

Our dedicated team of experienced and technically adept engineers stands ready to meet all customer technical requirements, tailoring solutions to their specific needs while offering expert guidance. Equipped with cutting-edge design software including E-Plan and Auto-CAD, our design team operates at the forefront of technological innovation. With a commitment to excellence, our motto embodies the pursuit of 'Engineering With Perfection', ensuring that every system delivered to our customers is crafted with precision and ingenuity. From concept to execution, we prioritize customer satisfaction and strive to exceed expectations through our unparalleled engineering expertise.

Fabrication & Painting

In our state-of-the-art fabrication facility, efficiency and precision are paramount, ensuring the rapid production of smooth, impeccably finished panels. Our paint shop boasts an advanced 8-tank process meticulously designed for the pretreatment of CRCA/GI sheets, eliminating any traces of oil, dust, or rust before the application of powder coating. Within our powder coating booth, equipped with a powder coating chamber, precision powder coating guns, and an electric oven, our skilled technicians apply a meticulous process. The cubicles undergo thorough chemical treatment, including derusting, pickling, and phosphating, before receiving two coats of zinc chromate with red oxide primer. Following meticulous putty work, the cubicles receive two final coats of a light grey shade, typically No. RAL 7032 or a shade approved by the customer. Each coat is meticulously stove-dried to ensure optimal adhesion and durability, with a paint thickness ranging between 60 to 80 microns. Our commitment to quality and attention to detail ensure that every panel leaving our facility meets the highest standards of performance and aesthetics, satisfying the diverse needs of our clientele.

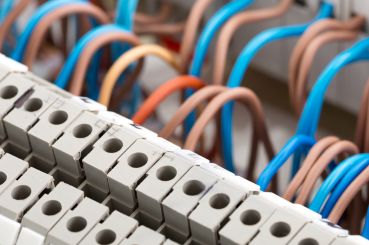

Wiring & Termination

Different type of harnesses are being used for various starters meter wiring etc, as per IS-8623 standards. All components/instruments in the panel are leveled with proper marking which enable even a layman to repair the equipments. The standard harnesses enable easy inter-changeability of feeders 1 / 1.5 sq mm copper flexible wire is used for control wiring. All cable ends are thimbled and starters are wired up to ready to use termination point.

Different type of harnesses are being used for All panels shall be completely factory wire ready for connecting to the equipment. All control wiring will be done by PVC insulated copper wire of sizes 1 / 1.5 sq mm fitted with identifications color ferrules Termination of wires on the both ends will be by using cable lugs wiring shall be properly dressed bunched and supported by ‘P’ clips.

Door Hinges & Knobs

The doors are designed specially to provide total sealing. The door hinges are designed to accommodate the door on easily recoverable and replaceable pins with soft rubber gaskets for complete dust proof sealing.

Accessories

All accessories used are of reputed makes companies and have been selected after vigorous scrutiny standards ensuring long life performance.

India's Leading Manufacturers & Exporters of: Electrical Control Panels, Cable Trays and Servo Voltage Stabilizers

India's Leading Manufacturers & Exporters of: Electrical Control Panels, Cable Trays and Servo Voltage Stabilizers