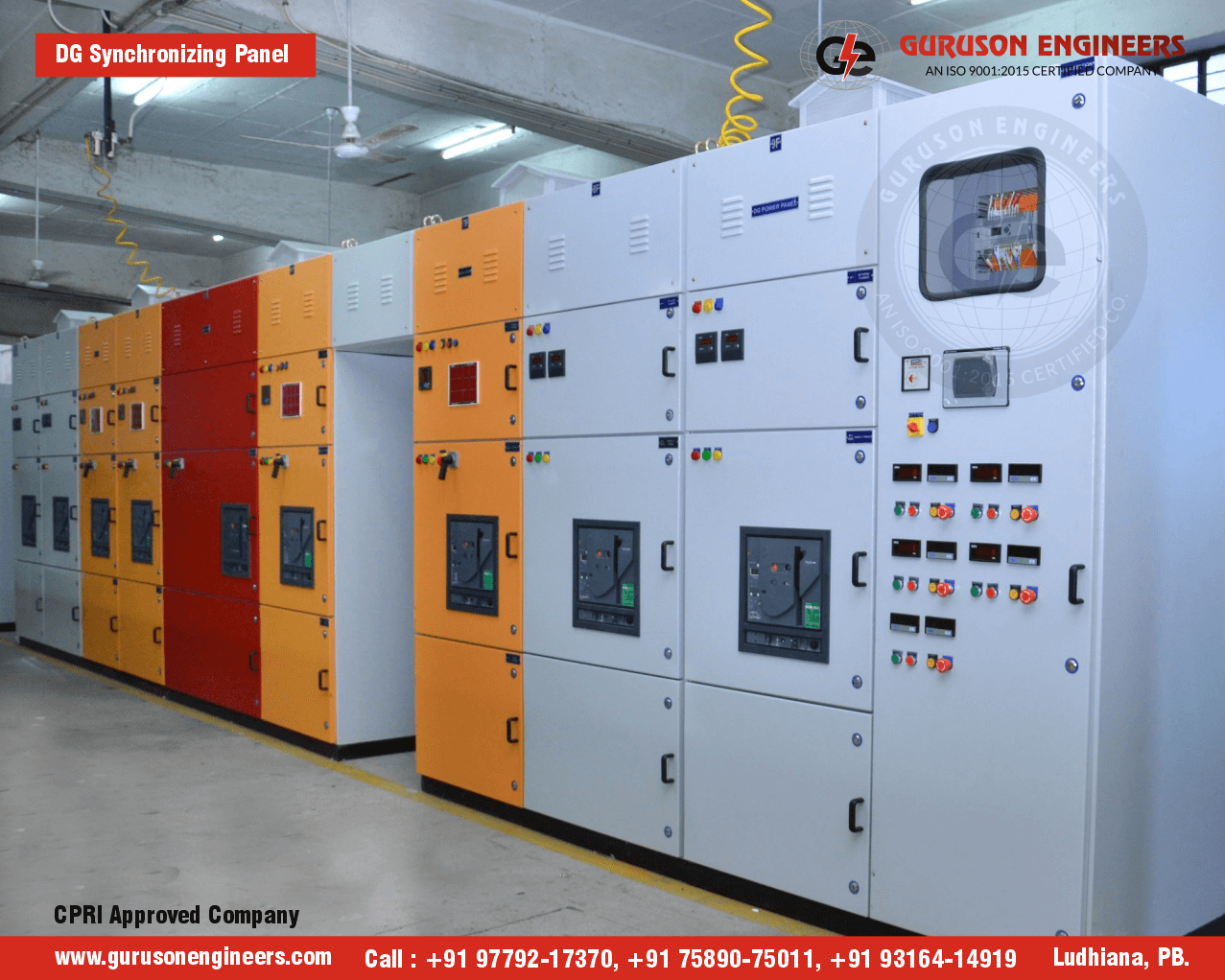

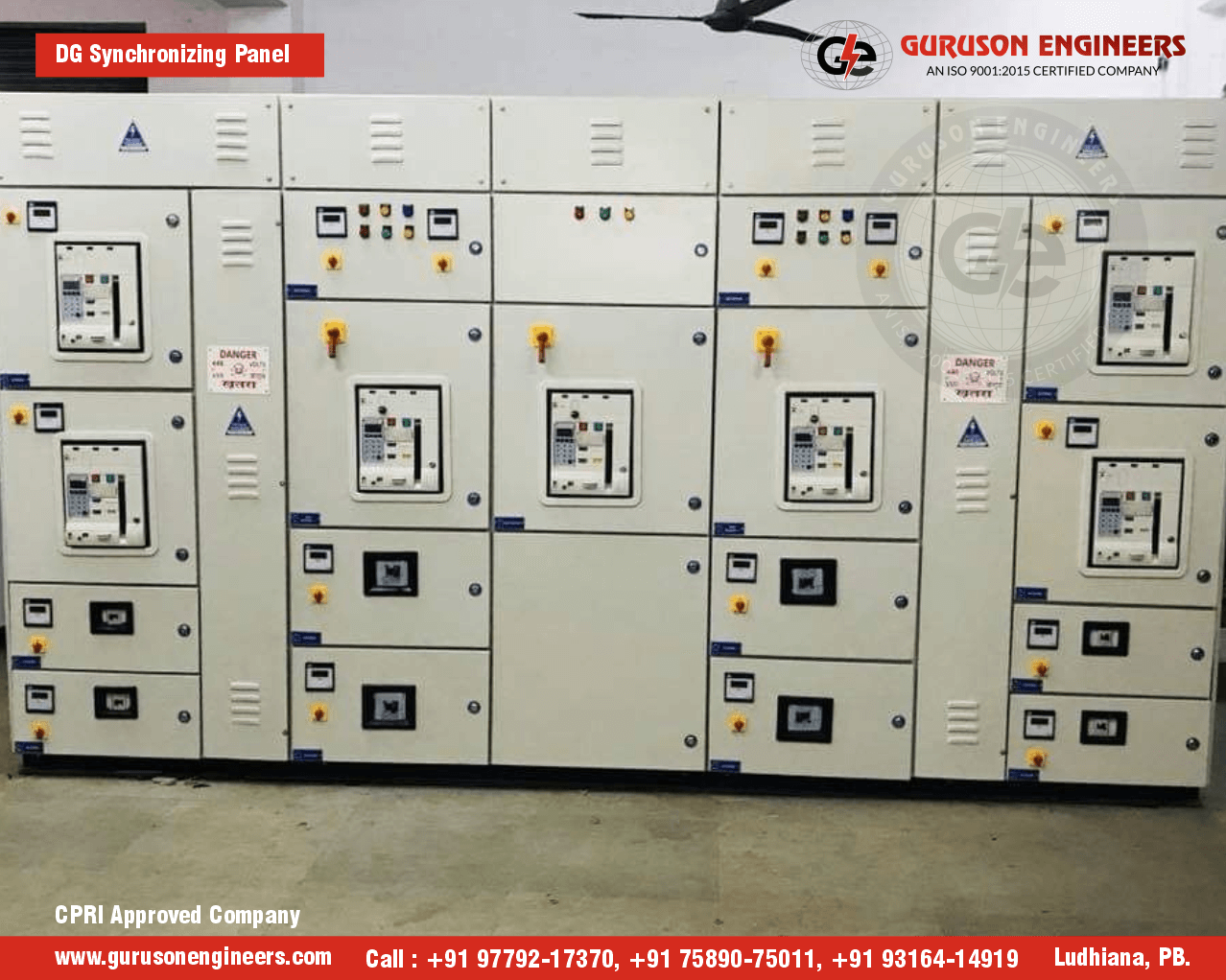

DG Synchronizing Panels

We take pride in presenting our meticulously crafted DG Synchronizing Panel, meticulously engineered to seamlessly integrate with diverse power system requirements. Engineered to exacting standards, our panel embodies a synergy of quality components and cutting-edge process technology. Offering versatility, it comes equipped with both auto and manual control options, ensuring smooth and hassle-free operations. At the heart of our design philosophy lies a commitment to reliability, underpinned by the utilization of RITTAL Panels and DEIF Controllers for DG Sync Panels. With a rated service voltage and frequency of 415 V & 50 Hz respectively, our Synchronizing Panel stands as a testament to our dedication to delivering excellence in every aspect. From conception to execution, each element is meticulously curated to uphold the highest standards, ensuring optimal performance and durability. Trust in our Synchronizing Panel to synchronize your power systems seamlessly, elevating efficiency and reliability to new heights.

Tailored Solutions for Every Industry:

At the core of our offerings lies a commitment to providing tailored solutions that cater precisely to your unique requirements. Our Synchronizing Panel epitomizes this ethos, meticulously designed to harmonize with diverse power system configurations. Built with a keen understanding of industry demands, we employ a bespoke approach, customizing each panel to match specific needs.

Maximizing Efficiency and Safety:

In our relentless pursuit of excellence, we prioritize not only maximizing efficiency but also ensuring the utmost safety in every aspect of our Synchronizing Panel design. Through meticulous engineering and stringent quality control measures, we strive to optimize operational efficiency, minimizing downtime and maximizing productivity. Each component is carefully selected and integrated to enhance system performance while maintaining the highest safety standards.

Construction features: The panel will be metal enclosed, sheet steel cubical pattern, extendable type dead front, floor / wall mounting type & suitable for indoor / outdoor mounting.

The panel boards will be totally enclosed type, dust and vermin proof. Synthetic rubber gasket between all adjacent units and beneath all covers will be provided to render the just and vermin proof to provide a degree of protection of IP 45. All doors and covers will be fully gasketed with synthetic rubber and will be lockable.

The panel boards will be fabricated with CRCA sheet steel of thickness not less than 1.6 / 2.0 mm and will be folder and braced as necessary to provide a rigid for all components. The doors and covers will be constructed from CRCA sheet steel of thickness 1.6 mm. Joints of any kind in sheet metal will be elect. Welded and all welding slag ground off and welding pit wiped smooth plumber metal.

All panels and covers will be properly fitted and square with the frame. The holes in the panel will be correctly positioned.

Fixing screws will enter holes tapped into an adequate thickness of metal or provided with hank nuts. Self-threading screws will not be used in the construction of the switchboards.

Different type of harnesses are being used for various starters meter wiring etc, as per IS-8623 standards. All components/instruments in the panel are leveled with proper marking which enable even a layman to repair the equipments. The standard harnesses enable easy inter-changeability of feeders 1 / 1.5 sq mm copper flexible wire is used for control wiring. All cable ends are thimbled and starters are wired up to ready to use termination point.

Different type of harnesses are being used for All panels shall be completely factory wire ready for connecting to the equipment. All control wiring will be done by PVC insulated copper wire of sizes 1 / 1.5 sq mm fitted with identifications color ferrules Termination of wires on the both ends will be by using cable lugs wiring shall be properly dressed bunched and supported by ‘P’ clips.

The doors are designed specially to provide total sealing. The door hinges are designed to accommodate the door on easily recoverable and replaceable pins with soft rubber gaskets for complete dust proof sealing.

The cubicles are chemically treated with pretreatment chemical i.e derusting, pickling and phosphating prior to two coats of zinc chromate with red oxide primer with putty work and with two final coats of light grey shade No. RAL 7032 or approved shade of customers. Each coat of paint well be properly stove & paint thickness will be not less than 60 to 80 microns.

All accessories used are of reputed makes companies and have been selected after vigorous scrutiny standards ensuring long life performance.

India's Leading Manufacturers & Exporters of: Electrical Control Panels, Cable Trays and Servo Voltage Stabilizers

India's Leading Manufacturers & Exporters of: Electrical Control Panels, Cable Trays and Servo Voltage Stabilizers